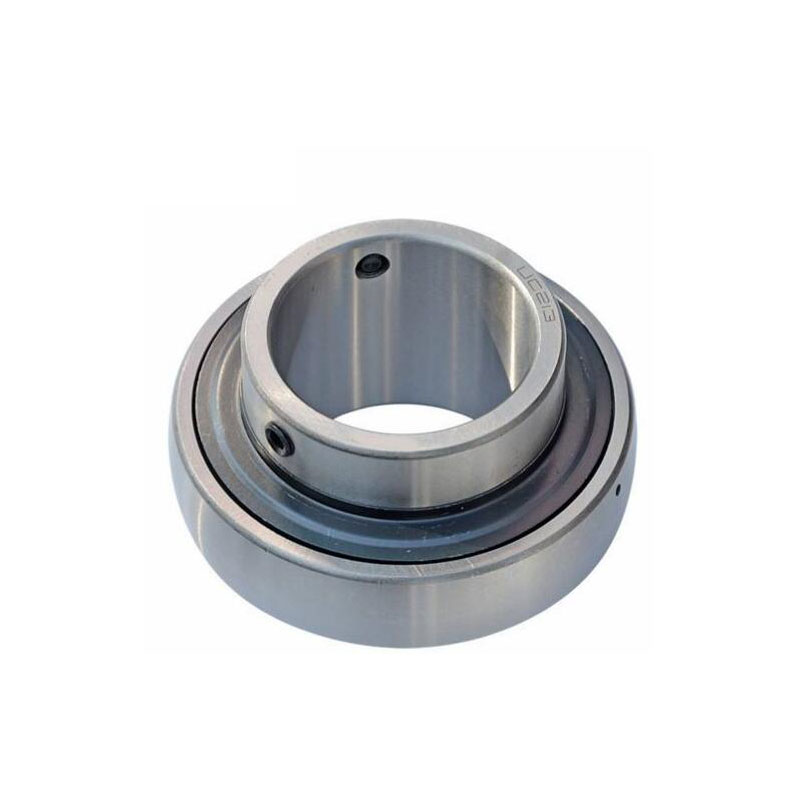

China Factory for Pillow Block Flange Bearing - Deep Groove Ball Bearings 6200 Series – Shining Industry

China Factory for Pillow Block Flange Bearing - Deep Groove Ball Bearings 6200 Series – Shining Industry Detail:

BEARING PARAMETERS

Single row deep groove ball bearings come in three numerical series representing the size and load capacity of each. They are:

6000 Series - Extra Light Ball Bearings - Ideal for limited space applications

6200 Series - Light Series Ball Bearings - Balanced between space and load capacity

6300 Series - Medium Series Ball Bearings - Ideal for heavier load capacity applications

The parameters of 6200 series are as follows:

|

Bearing No. |

I.D |

O.D |

W |

Load Rating(KN) |

Steel Ball Parameter |

Max speed |

Unit Weight |

|||

|

d |

D |

B |

Dynamic |

Static |

No. |

Size |

Grease |

Oil |

||

|

mm |

mm |

mm |

Cr |

Cor |

mm |

r/min |

r/min |

kg |

||

|

6200 |

10 |

30 |

9 |

5.10 |

2.39 |

8 |

4.7630 |

25000 |

30000 |

0.032 |

|

6201 |

12 |

32 |

10 |

6.10 |

2.75 |

7 |

5.9530 |

22000 |

26000 |

0.037 |

|

6202 |

15 |

35 |

11 |

7.75 |

3.60 |

8 |

5.9530 |

19000 |

23000 |

0.045 |

|

6203 |

17 |

40 |

12 |

9.60 |

4.60 |

8 |

6.7470 |

18000 |

21000 |

0.065 |

|

6204 |

20 |

47 |

14 |

12.80 |

6.65 |

8 |

7.9380 |

16000 |

18000 |

0.106 |

|

6205 |

25 |

52 |

15 |

14.00 |

7.85 |

9 |

7.9380 |

13000 |

15000 |

0.128 |

|

6206 |

30 |

62 |

16 |

19.50 |

11.30 |

9 |

9.5250 |

11000 |

13000 |

0.199 |

|

6207 |

35 |

72 |

17 |

25.70 |

15.30 |

9 |

11.1120 |

9800 |

11000 |

0.288 |

|

6208 |

40 |

80 |

18 |

29.10 |

17.80 |

9 |

12.0000 |

8700 |

10000 |

0.366 |

|

6209 |

45 |

85 |

19 |

32.50 |

20.40 |

10 |

12.0000 |

7800 |

9200 |

0.407 |

|

6210 |

50 |

90 |

20 |

35.00 |

23.20 |

10 |

12.7000 |

7100 |

8300 |

0.463 |

|

6211 |

55 |

100 |

21 |

43.50 |

29.20 |

10 |

14.2880 |

6400 |

7600 |

0.607 |

|

6212 |

60 |

110 |

22 |

52.50 |

36.00 |

10 |

15.0810 |

6000 |

7000 |

0.783 |

|

6213 |

65 |

120 |

23 |

57.50 |

40.00 |

10 |

16.6690 |

5500 |

6500 |

0.990 |

|

6214 |

70 |

125 |

24 |

62.00 |

44.00 |

11 |

16.4620 |

5100 |

6000 |

1.070 |

|

6215 |

75 |

130 |

25 |

66.00 |

49.50 |

11 |

17.4620 |

4800 |

5600 |

1.180 |

|

6216 |

80 |

140 |

26 |

72.50 |

53.00 |

11 |

18.2560 |

4500 |

5300 |

1.400 |

|

6217 |

85 |

150 |

28 |

83.50 |

64.00 |

11 |

19.8440 |

4200 |

5000 |

1.790 |

|

6218 |

90 |

160 |

30 |

96.00 |

71.50 |

10 |

22.2250 |

4000 |

4700 |

2.150 |

|

6219 |

95 |

170 |

32 |

109.00 |

82.00 |

10 |

24.0000 |

3700 |

4400 |

2.620 |

|

6220 |

100 |

180 |

34 |

122.00 |

93.00 |

10 |

25.4000 |

3500 |

4200 |

3.190 |

BEARING CONSTRUCTION

BEARING MATERIALS

The performance and reliability of rolling bearings are greatly affected by the materials which the bearing components are made from.BXY bearing rings and balls are made of high quality of GCr15 vacuum-degassed bearing steel.Chemical composition of GCr15 bearing steel is basically equivalent to some representative bearing steel as the chart shown below:

|

Standard Code |

Material |

Analysis(%) |

||||||

|

C |

Si |

Mn |

Cr |

Mo |

P |

S |

||

|

GB/T |

GCr15 |

0.95-1.05 |

0.15-0.35 |

0.25-0.45 |

1.40-1.65 |

≦0.08 |

≦0.025 |

≦0.025 |

|

DIN |

100Cr6 |

0.95-1.05 |

0.15-0.35 |

0.25-0.45 |

1.40-1.65 |

≦0.030 |

≦0.025 |

|

|

ASTM |

52100 |

0.98-1.10 |

0.15-0.35 |

0.25-0.45 |

1.30-1.60 |

≦0.10 |

≦0.025 |

≦0.025 |

|

JIS |

SUJ2 |

0.98-1.10 |

0.15-0.35 |

≦0.50 |

1.30-1.60 |

≦0.025 |

≦0.025 |

|

BEARING PACKING

Our packaging is also very variable, the purpose is to meet the needs of different customers.The commonly used packages are as follows:

1.Industrial package+outer carton+pallets

2.Single box+outer carton+pallets

3.Tube package+middle box+outer carton+pallets

4.According to your requirements

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer you excellent services to each individual client, but also are ready to receive any suggestion offered by our buyers for China Factory for Pillow Block Flange Bearing - Deep Groove Ball Bearings 6200 Series – Shining Industry , The product will supply to all over the world, such as: Vancouver, Argentina, Swiss, Since the establishment of our company, we've realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down these barriers to ensure you get what you want to the level you expect, when you want it.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.